2. Features asymmetric bidirectional seal profile for piston sealing with compact dimensions and integrated oil reservoir functionality;

3. Constructed with octagonal aluminum tubing (non-tie-rod design), offering enhanced corrosion resistance. Equipped with built-in sensor mounting grooves for simplified installations;

4. Compact stroke length compared to ISO 15662 compliant cylinders of equivalent bore sizes in SAU series;

5. Incorporates adjustable cushioning mechanism for smooth end-of-stroke deceleration;

6. Shares universal mounting accessories compatibility with SC series cylinders;

7. Utilizes high-temperature resistant sealing compounds for operational range of 0-150°C.

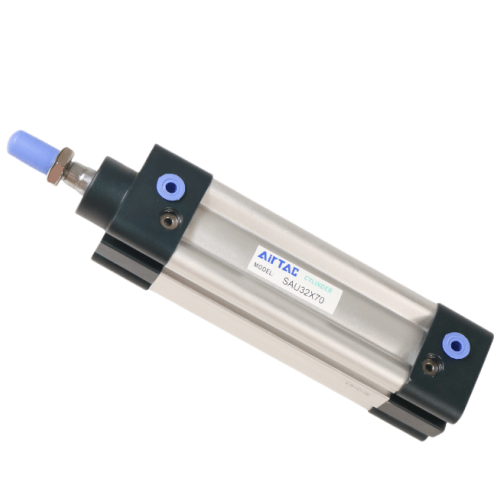

Category: Standard Cylinders | Brand: AIRTAC® | Series: SAU

AirTAC SAU63X45 Standard Cylinder Specifications

- Model: SAU63X45 (Standard Air Cylinder ISO 6432)

- Type: Double-acting pneumatic cylinder

- Bore size: Ø63 mm (±0.1mm tolerance)

- Stroke: 45 mm (adjustable cushioning)

- Operating pressure: 0.15-0.9 MPa (21-130 PSI)

- Ambient temperature: -20℃ to 80℃ (NBR seals)

- Cushioning type: Air cushion adjustable at both ends

- Port size: 1/4" NPT (G1/4 optional)

- Piston rod thread: M14×1.5 (external)

- Mounting types: Basic front flange MF1, optional rear pivot

- Weight: 1.28 kg (excluding accessories)

- Dimensions:

- Total length (L): 228 mm (at mid-stroke)

- Body width (W): 75 mm (mounting flange edge)

- Height (H): 63 mm (cylinder bore diameter)

- Material:

- Cylinder tube: Aluminum alloy (hard anodized)

- Piston rod: Chrome-plated carbon steel

- End caps: Die-cast aluminum

- Seal material: Nitrile rubber (NBR) standard

- Protection class: IP65 (dust-tight & water jet resistant)

High-precision industrial cylinder featuring twin-piston cushioning and anti-rotation guide mechanism. The hard chrome-plated rod with integrated scraper reduces contamination ingress, making it ideal for repetitive motion tasks. Requires 40μm filtered compressed air with ISO VG32 lubricator oil (optional oil-free operation).

- Clamping fixtures in CNC machining centers

- Sheet metal punching press actuation

- Automated assembly line part ejection

- Plastic injection molding machine core pulls

- Conveyor gate control systems

- Maintain 0.5mm minimum alignment tolerance during mounting

- Apply thread sealant (LOCTITE 545) to port connections

- Lubricate every 3,000km stroke distance or 6 months

- Avoid side load exceeding 30N (use guide units if needed)

| Property | Property Value |

|---|---|

| sku | SAU63X45 |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | Non-magnetic |

| Bore Diameter | 63mm |

| Stroke | <45mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.