2. Features asymmetric bidirectional seal profile for piston sealing with compact dimensions and integrated oil reservoir functionality;

3. Constructed with octagonal aluminum tubing (non-tie-rod design), offering enhanced corrosion resistance. Equipped with built-in sensor mounting grooves for simplified installations;

4. Compact stroke length compared to ISO 15662 compliant cylinders of equivalent bore sizes in SAU series;

5. Incorporates adjustable cushioning mechanism for smooth end-of-stroke deceleration;

6. Shares universal mounting accessories compatibility with SC series cylinders;

7. Utilizes high-temperature resistant sealing compounds for operational range of 0-150°C.

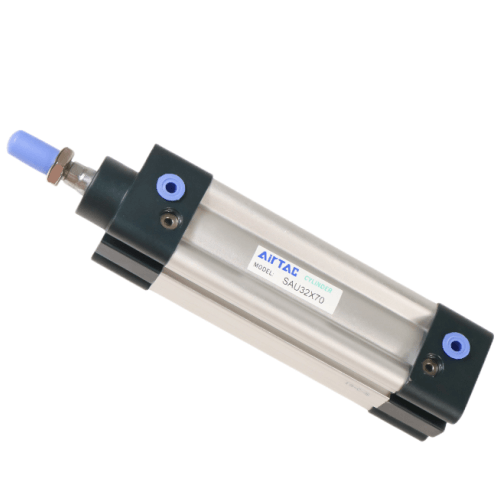

Category: Standard Cylinders | Brand: AIRTAC® | Series: SAU

AirTAC SAU Standard Cylinder SAU63X800S Full Specifications

- Model: SAU63X800S

- Bore size: 63 mm

- Stroke: 800 mm

- Operating pressure: 0.05–0.9 MPa

- Cushion type: Adjustable air cushion (both ends)

- Mounting style: Basic type (MF1) with standard foot mounting

- Port size: 1/4" NPT (G1/4 optional)

- Temperature range: -20℃ to 80℃

- Cylinder material: Aluminum alloy (hard anodized)

- Piston rod material: Chrome-plated steel (SUS304)

- Seal material: NBR + Polyurethane combination

- Weight: 4.8 kg (without accessories)

- Dimensions:

- Total length: 982 mm (at mid-stroke)

- Body diameter: 80 mm

- Mounting base: 100×45 mm

- Rod end thread: M20×1.5

- ISO standard: 6432 compliant

- Max theoretical thrust: 2,800 N @0.5 MPa

- Lubrication: Pre-lubricated (Oil-free operation possible)

High-precision industrial cylinder designed for heavy-duty linear motion applications. Features dual adjustable pneumatic cushions for smooth deceleration and impact reduction. The hard-anodized barrel provides exceptional wear resistance, while the triple-lip seal design ensures leak-free operation even under continuous cycling.

- Automated assembly line material handling

- Press machine ejection systems

- Plastic injection molding machine gates

- Large-scale CNC fixture clamping

- Packaging line pusher mechanisms

1. Ensure proper alignment with guided rail systems for long-stroke applications

2. Maintain 0.3-1.0 MPa lubricated air pressure (ISO 8573-1 class 4)

3. Adjust cushion needles gradually - turn 1/4 rotation per adjustment

4. Recommended maintenance: Relubricate every 500 km cumulative travel distance

| Property | Property Value |

|---|---|

| sku | SAU63X800S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature:-20-70°C Speed Range:30-800mm/s |

| Port Size | PT3/8 |

| Magnet | S-Magnetic |

| Bore Diameter | 63mm |

| Stroke | 800mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.