2. SGC series features a custom bidirectional piston seal design with integrated oil reservoir for compact dimensions and enhanced lubrication. (Note: SG series adopts dual Y-type unidirectional seals with compensation mechanism for extended service life and low actuation pressure);

3. SG series utilizes steel tube construction for superior impact resistance;

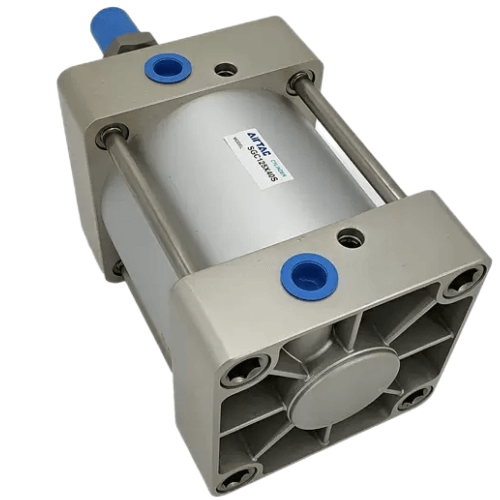

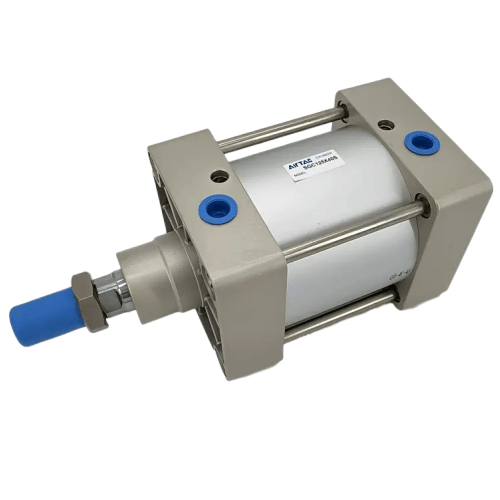

4. SGC series employs aluminum tube configuration with optional magnetic piston for sensor compatibility (magnetic option unavailable for SG series);

5. Precision-adjustable cushioned stroke control ensures smooth operation;

6. Comprehensive selection of cylinder sizes and mounting accessories available for system integration;

7. High-temperature resistant sealing materials enable operational range of 0-150°C.

Category: Standard Cylinders | Brand: AIRTAC | Series: SGC

AirTAC SGC125X80SH Standard Cylinder Specifications

- Model: SGC125X80SH

- Series: ISO 15552 compliant standard cylinder

- Bore size: 125 mm

- Stroke: 80 mm

- Action type: Double-acting

- Operating pressure: 0.05–0.9 MPa (Max. pressure resistance: 1.35 MPa)

- Cushioning: Adjustable SH-type buffer (5-15mm cushion length)

- Port size: G3/8 (ISO standard thread)

- Piston rod diameter: 25 mm (chrome-plated steel)

- Material: Aluminum alloy barrel, hardened end caps

- Seal material: NBR (nitrile rubber) standard / PU optional

- Ambient temperature: -20℃ to 80℃ (no ice formation)

- Weight: 6.8 kg (without accessories)

- Dimensions:

- Total length (L): 290 mm (at mid-stroke position)

- Barrel outer diameter: 146 mm

- Mounting height: 160 mm (center-to-center bolt spacing)

- Rod end thread: M16x1.5

- Repeat positioning accuracy: ±0.5 mm

- Lubrication: Pre-lubricated (relubrication interval: 2,000 km travel)

The SGC125X80SH industrial cylinder delivers 15.4kN thrust at 0.7MPa, featuring precision-ground stainless steel guide rods for anti-rotation stability. Its triple-seal design (rod seal, buffer seal, and wiper) ensures ≤0.5mm3/min air leakage. The magnetic piston version (add "-M" suffix) enables position sensing compatibility.

- Press machine ejection systems

- Automotive welding fixture clamping

- Palletizing robot end-effectors

- Injection molding machine core pulls

- Steel mill conveyor gate actuators

- Use M12 mounting bolts (Grade 8.8 or higher)

- Maintain 0.5-1mm alignment tolerance during flange mounting

- For vertical mounting, install rod-end down to prevent condensate ingress

- Buffer adjustment: Turn clockwise to soften cushioning (max 3 full rotations)

▶ Daily check: Inspect rod surface for scoring. Annual maintenance: Replace wear bands if lateral play exceeds 0.8mm. Always use 5μm filtered air with ISO VG32 oil mist lubrication.

| Property | Property Value |

|---|---|

| sku | SGC125X80SH |

| Seal Material | FKM |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT 1/2 |

| Magnet | S-Magnetic |

| Cushion Stroke | <40mm> |

| Bore Diameter | 125mm |

| Stroke | 80 mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.