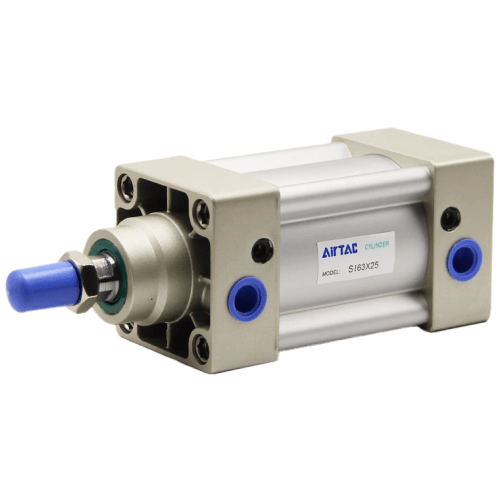

2. Piston features bidirectional Y-seal structure with cushioning function, offering extended service life and low friction resistance;

3. Aluminum barrel with cruciform reinforcement and black-anodized piston rod for enhanced corrosion resistance;

4. Precision machined cylinder surface ensures smooth operation;

5. Multiple cylinder specifications and mounting accessories available for flexible configurations.

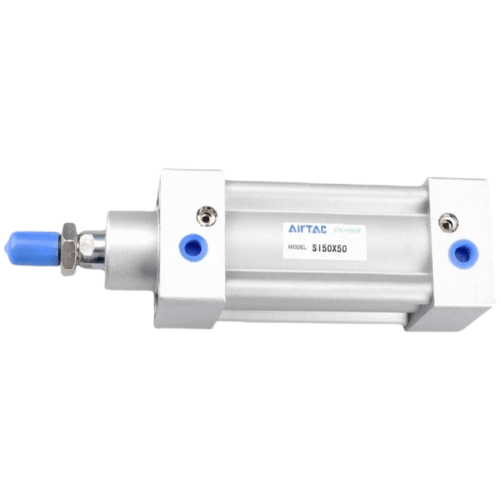

Category: Standard Cylinders | Brand: AIRTAC | Series: SI125

AirTAC SI125AX120S Standard Cylinder Specifications

- Model: SI125AX120S

- Type: ISO 15552 compliant double-acting pneumatic cylinder

- Bore size: 125 mm

- Stroke: 120 mm (adjustable cushioning)

- Operating pressure: 0.05–1.0 MPa

- Cushion type: Adjustable rubber buffer (both ends)

- Mounting style: AX series front flange with mounting holes

- Port size: G1/2 (BSPP thread)

- Operating temperature: -20℃ to 80℃

- Piston rod material: Chrome-plated carbon steel (Cr-Mo)

- Tube material: Anodized aluminum alloy

- Seal material: NBR (nitrile rubber) standard / optional PU

- Weight: 5.8 kg (without accessories)

- Dimensions:

- Extended length: 318 mm

- Retracted length: 198 mm

- Body diameter: Φ125 mm

- Mounting flange thickness: 20 mm

- Rod end thread: M20×1.5 (male)

- Max theoretical thrust: 1,227 N @ 0.63 MPa

- ISO standard: 15552 (formerly ISO 6431)

High-performance industrial cylinder featuring wear-resistant construction and precision honed inner tube surface (Ra ≤0.2μm). Equipped with magnetic piston (D-M9 connector) for position sensing compatibility. The double lip seal design ensures ≤0.5 mm/s low creep speed stability under load. Includes anti-rotation guide for torque resistance in vertical applications.

- Heavy-duty press machinery ejection systems

- Automotive assembly line clamping fixtures

- Plastic injection molding machine core pullers

- Steel mill conveyor gate actuators

- Packaging machine lid press mechanisms

| Property | Property Value |

|---|---|

| sku | SI125AX120S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 80°C Speed Range: 30-500 mm/s |

| Port Size | PT 1/2 |

| Piston Rod Material | SUS420J2 |

| Magnet | S-Magnetic |

| Bore Diameter | 125mm |

| Stroke | 120mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.