2. Piston features a durable Y-type axial seal with self-compensating function, providing extended service life and low friction resistance

3. Aluminum tube with crisscross reinforcement design and anodized tie rods for enhanced corrosion resistance

4. Adjustable cushioning for smooth operation

5. Multiple configurations available with comprehensive cylinder variants and mounting accessories for flexible system integration

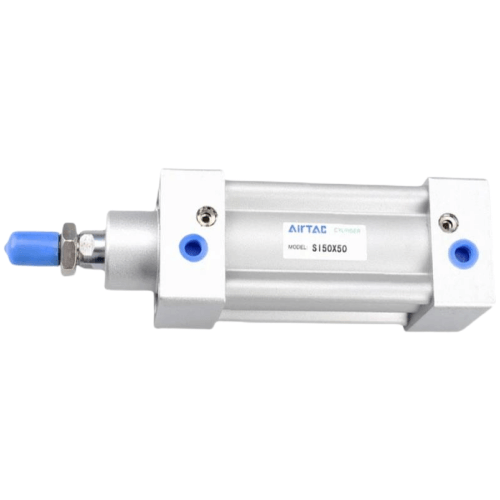

Category: Standard Cylinders | Brand: AirTAC | Series: SI50

AirTAC SI50AX500 Standard Cylinder Specifications

- Model: SI50AX500

- Type: ISO 6432 compliant single-acting/pneumatic return cylinder

- Bore size: 50 mm

- Stroke: 500 mm (customizable 25-1000mm)

- Operating pressure: 0.05-1.0 MPa

- Temperature range: -20℃ to 80℃

- Buffer type: Adjustable rubber cushion (both ends)

- Port size: G1/8 (NPT1/4 optional)

- Mounting style: Basic type (MF1) with optional foot/mounting flange

- Piston rod thread: M16×1.5 (external)

- Cylinder material: Anodized aluminum alloy tube

- Seal material: NBR/PU (FDA compliant options available)

- Protection rating: IP54 (standard), IP67 with optional wiper

- Lubrication: Pre-lubricated (use ISO VG32 hydraulic oil if needed)

- Repeat positioning accuracy: ±0.5 mm

- Max speed: 1000 mm/s

- Durability: 5,000 km (tested under 0.5 MPa, no-load)

- Weight: 2.3 kg (excluding mounting accessories)

- Dimensions:

- Total length: 500 + 87 mm (stroke + end caps)

- Body diameter: 50 mm (outer)

- Mounting height: 60 mm (centerline to base)

High-force pneumatic actuator with precision honed tube and chrome-plated piston rod. Features dual anti-rotation guide slots (180° apart) and corrosion-resistant construction. Ideal for vertical/horizontal thrust applications requiring extended stroke accuracy. Optional magnetic piston version (SI50AX500-M9T) available for position sensing.

- Industrial automation: Press machine ejection systems

- Material handling: Conveyor gate actuators

- Automotive: Welding fixture positioning

- Packaging: Case erector cylinder drives

- Machine tools: Chip removal mechanisms

- Maintain 0.5-1mm alignment tolerance during mounting

- Use locknuts (M16) with 25-35 N·m torque for rod end connections

- For vertical mounting, install air vent filter in exhaust port

- Max side load: 150N at mid-stroke

- Do NOT exceed 1.2 MPa burst pressure

- Rebuild recommended after 3 million cycles

- Buffer adjustment requires 0.5 MPa minimum pressure

| Property | Property Value |

|---|---|

| sku | SI50AX500 |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20℃ to 80℃ Speed Range: 30-800 mm/s |

| Port Size | PT1/4 |

| Piston Rod Material | SUS420J2 |

| Magnet | Non-magnetic |

| Bore Diameter | <50mm> |

| Stroke | 500mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.