2. Piston sealing features dual-locked Y-type axial sealing structure with dust scraping capability, delivering extended service life and low friction resistance;

3. Aluminum tube with cross-shaped reinforcement and anodized tie rods for enhanced corrosion resistance;

4. Optimized cushion adjustment system with stable stroke control;

5. Multiple bore sizes and mounting accessories available for flexible configuration.

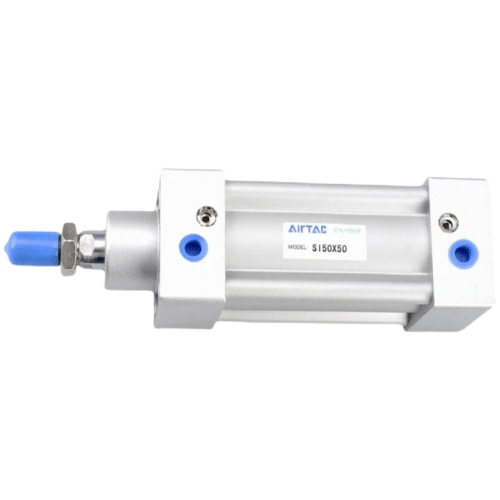

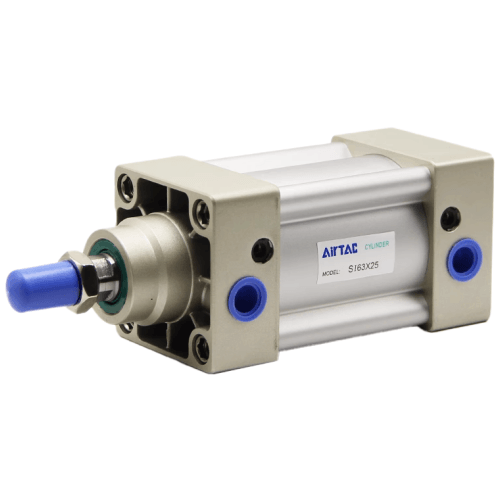

Category: Standard Cylinders | Brand: Airtac | Series: SI63

AirTAC SI63X140S Standard Cylinder Specifications

- Model: SI63X140S

- Bore size: 63 mm

- Stroke: 140 mm

- Type: Double-acting cylinder

- Mounting options: Basic type (MF1), front/rear flange (MP4/MP5), foot mounting (MA1)

- Piston rod thread: M16×1.5

- Operating pressure: 0.15–0.9 MPa

- Cushioning: Adjustable air cushion (both ends)

- Temperature range: -20℃ to 80℃

- Seal material: NBR (nitrile rubber) standard, optional polyurethane

- Ambient humidity: ≤95% RH

- Weight: 2.7 kg (aluminum body)

- Dimensions: 240mm(L) × 108mm(W) × 108mm(H) (including mounting accessories)

- Rod end type: Female thread with pivot eye (ISO 12345 standard)

- Port size: G1/8 (M5 available as option)

- Max theoretical thrust: 2800N at 0.63MPa

- Speed range: 50–800 mm/s (with cushion adjustment)

- Protection rating: IP54 (standard), IP67 optional

A high-rigidity industrial cylinder featuring chrome-plated piston rod and precision honed aluminum barrel. The SI63X140S delivers 4.9kgf/cm² operating force with ±0.5mm repeat positioning accuracy. Integrated shock absorbers reduce end-impact noise by 15dB compared to basic models. Compatible with AirTAC's full range of magnetic sensors (D-A93 series recommended).

- Palletizing robot arm actuation

- Injection molding machine ejection systems

- CNC machine tool clamping mechanisms

- Automotive assembly line positioning

- Food processing conveyor gate control

- Replace rod wipers every 5 million cycles

- Inspect piston seal leakage every 2,000 operating hours

- Lubrication interval: 100km of cumulative stroke distance

| Property | Property Value |

|---|---|

| sku | SI63X140S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20℃ to 80℃ Speed Range: 30-800 mm/s |

| Port Size | PT3/8 |

| Piston Rod Material | Medium Carbon Steel |

| Magnet | S-Magnetic |

| Bore Diameter | 63mm |

| Stroke | <140mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.