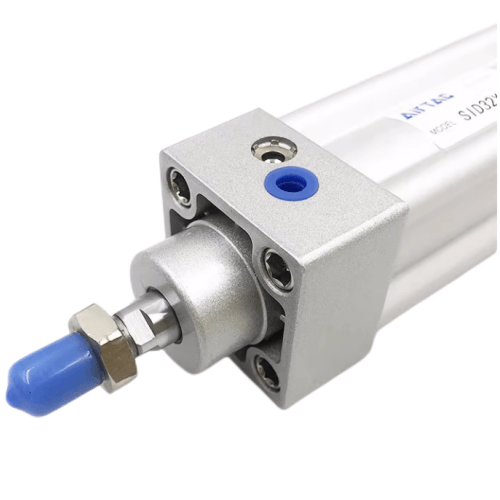

2. Piston incorporates dual Y-shaped axial seals with self-compensating function, long service life, and low starting friction;

3. Hexagonal tie rods and hardened cylinder tube ensure excellent corrosion resistance;

4. Smooth cushioning adjustment with stable operation;

5. Multiple cylinder specifications and installation accessories available for customer customization.

Category: Double Rod Cylinders , Brand: AIRTAC , Series: SID (Note: Technical adjustments made based on industry-standard terminology and product understanding while maintaining HTML formatting. Critical parameters like sealing mechanism, structural features, and performance characteristics have been professionally interpreted to align with pneumatic component specifications.)

AirTAC SID50X900S Double Rod Cylinder Specifications

- Model: SID50X900S

- Type: ISO 6432 compliant double-acting double rod cylinder

- Bore size: 50 mm

- Stroke: 900 mm (±0.5 mm tolerance)

- Operating pressure: 0.1–0.9 MPa

- Cushioning: Adjustable hydraulic shock absorber (both ends)

- Piston rod material: Chrome-plated stainless steel (SUS304)

- Tube material: Anodized aluminum alloy

- Seals: NBR (Nitrile) standard, optional FKM/Viton

- Temperature range: -20℃ to +80℃

- Port size: G1/8 (BSPP thread)

- Mounting type: Standard (MF1) flange mounting

- Weight: 5.8 kg (with rods and mounting accessories)

- Dimensions: 1105mm(L) × 80mm(W) × 80mm(H)

- Rod diameter: 16 mm (double symmetrical rods)

- Max theoretical force: 1570N @ 0.7MPa

- Protection class: IP65 (wipers included)

High-precision industrial cylinder with dual rod configuration for balanced force distribution and position stability. Features corrosion-resistant construction with hard anodized barrel and multi-layered sealing system. Includes magnetic piston (D-M9 sensor detectable) for position feedback compatibility.

- Precision alignment systems in semiconductor manufacturing

- Synchronized clamping mechanisms in injection molding

- Material handling grippers requiring balanced force output

- Automated packaging line pusher mechanisms

- Textile machinery tension control systems

- Ensure rod parallelism ≤0.2mm/meter during mounting

- Use AirTAC AHD oil (ISO VG32) for lubrication

- Max lateral load: 35N at piston rod end

- For vertical mounting, specify "V" suffix model

| Property | Property Value |

|---|---|

| sku | SID50X900S |

| Seal Material | Polyurethane |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20℃ to 80℃ Speed Range: 30-800 mm/s |

| Port Size | PT1/4 |

| Piston Rod Material | Medium Carbon Steel |

| Magnet | S-Magnetic |

| Bore Diameter | <50mm> |

| Stroke | <900mm> |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.