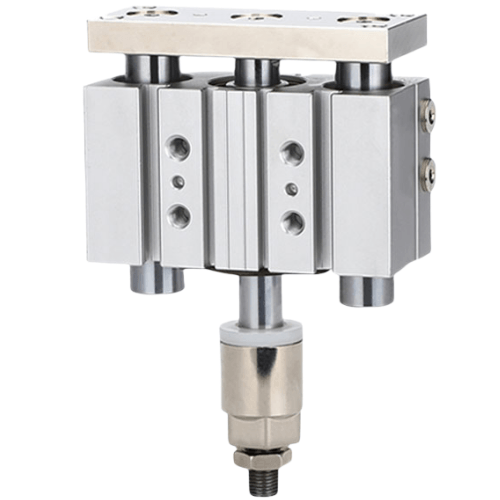

2. Dual guide rods manufactured from specialized bearing steel, guided by either linear bearings (ball-type) or bronze bushings, delivering exceptional torsion resistance and lateral load capacity. ★Note: Ball-type linear bearings: Ideal for lifting applications requiring high precision, superior load capacity, and low-friction movement. Bronze sliding bushings: Optimized for braking operations with radial loads, offering 2X greater lateral impact resistance and enhanced torsional rigidity compared to conventional brake cylinders.

3. Integrated design combines driving unit and guiding mechanism within a single body, eliminating additional accessories while maintaining minimal spatial requirements. Optional air inlet ports enable flexible installation.

4. Precision-engineered positioning holes on base surface, rear end face, and mounting plate (PA holes and XX holes in outline diagram) ensure accurate alignment for high-precision applications.

5. Four sensor grooves on body accommodate multiple sensor mounting configurations.

6. Proprietary structural design supports versatile mounting configurations across multiple orientations.

Category: Adjustable Cylinder | Brand: AIRTAC | Series: TCLJ

AirTAC TCLJ25X80-50S 3-Axis Adjustable Cylinder Specifications

- Model: TCLJ25X80-50S

- Type: Triple-axis adjustable pneumatic cylinder (ISO 6432 compliant)

- Bore size: 25mm

- Stroke: 80mm ±0.5mm

- Working pressure: 0.1–0.8 MPa

- Port size: M5×0.8 (G1/8 optional)

- Adjustment range: X/Y/Z axes ±3° (continuous fine-tuning via lockable dials)

- Mounting type: Side-mounted with 4×M5 threaded holes

- Piston rod material: Hard chrome-plated stainless steel (SUS304)

- Seal material: NBR (Nitrile) with wear-resistant ring

- Temperature range: -20℃ to 80℃

- Protection rating: IP40 (dust protected)

- Cushioning: Adjustable air cushion at both ends

- Weight: 1.2kg ±50g (excluding accessories)

- Dimensions: 145mm(L) × 60mm(W) × 45mm(H) (max extended position)

- Repeat positioning accuracy: ±0.1mm

- Max lateral load: 15N at full extension

Multi-axis alignment cylinder with precision-ground base plate and micrometer-style adjustment knobs. Features anti-vibration locking collars and corrosion-resistant anodized aluminum body. Designed for applications requiring sub-millimeter positional accuracy across three planes. Requires 5μm filtered lubricated air (ISO 8573-1 Class 3).

- PCB drilling/routing machine tool positioning

- Robotic end-effector alignment systems

- Optical lens assembly calibration stations

- Semiconductor wafer handling equipment

- Precision fixture adjustment in automotive jigs

- Used with AirTAC SC-332H magnetic reed sensor (sold separately)

- Compatible with AS4000 series modular brackets

- Recommended regulator: AR20-02BG with precision pressure gauge

| Property | Property Value |

|---|---|

| sku | TCLJ25X80-50S |

| Adjustable Stroke | <50mm> |

| Understood. Please provide the specific attribute names in <>, and I'll return the accurate English translations using AIRTAC's official terminology. Example: User input: <缸径> My output: Bore | Operating Temperature: -20°C to 70°C Speed Range: 30 to 500 mm/s |

| Port Size | PT1/8 |

| Magnet | S-Magnetic |

| Cushion Type | Bumper Pad |

| Bore Diameter | <25 mm> |

| Stroke | 80 mm |

Returns will be accepted for up to 15 days of Customer’s receipt or tracking number on Not used items. You, as a Customer, are obliged to inform us via email before you return the item, only in the case of:

- Received the wrong item.

- Item arrived not as expected (ie. damaged packaging).

- Item had defects.

- Over delivery time.

- The shipper does not allow the goods to be inspected before payment.

The returned product(s) must be in the original packaging, safety wrapped, undamaged and unworn. This means that the item(s) must be safely packed in a carton box for protection during transport, possibly the same carton used to ship to you as a customer.