Standard cylinder——SE Series

In accordance with ISO15552 and VDMA24562 standard

Standard cylinder——SE Series

In accordance with ISO15552 and VDMA24562 standard

Compendium of SE Series

ISO15552, VDMA24562 Standard cylinder

Bore size:32、40、50、63、80、100、125

Without tie rod

The square aluminum pipe without tie rod has good corrosion resistance

Four kinds of cylinder joints

- I Knuckle

- Y Knuckle

- Floating Joint

- Universal Joint

Multi-type cylinder

- SE:Double acting type

- SED:Double rod type

- SEJ:Adjustable stroke type

Adjustable air buffer

With adjustable air buffer on the front and back cover

With sensor switch groove

With sensor switch groove on the three sides of body, the counterpart sensor switch type is:CMSE / DMSE.

Multi-mounting accessories

LB、FA、FB、CA、CB、CR、FTC、TCM1、TCM2、TC

Criteria for selection: Cylinder thrust

[Table image placeholder — see page image below]

Installation and application

- When load changes in the work, the cylinder with abundant output capacity shall be selected.

- Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

- Necessary protection measure shall be taken in the environment with high humidity, mud dust or water drops, oil dust and welding dregs.

- Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

- The medium used by cylinder shall be filtered to 40 μm or below.

- Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

- The cylinder shall be carried out test run without load before application. Prior to run, buffer should be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

- The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

- If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

ISO15552 Standard cylinder

SE Series

Symbol

- SE

- SED

- SEJ

- SE-S

- SED-S

- SEJ-S

Product feature

- ISO15552 and VDMA24562 standard cylinder;

- The piston seal is composed of two Y-shape one-way seal structure, which has compensation function, long service life and low start-up pressure;

- The square aluminum pipe without tie rod has good corrosion resistance;

- The buffer adjustment of cylinder is smooth and steady;

- Cylinders and accessories for installation with several specifications are optional.

Specification

[Specification table placeholder — see page image below]

Stroke

[Stroke table placeholder — see page image below]

Ordering code

Ordering code

SE 80 □ × 50 S □ □ □

SED80 □ × 50 S □ □ □

SEJ 80 □ × 50-20 S □ □ □

| ① Model | ② Bore size | ③ Rod Material | ④ Stroke | ⑤ Adjustable stroke | ⑥ Magnet | ⑦ Mounting type [Note1] | ⑧ Seals Material | ⑨ Thread type |

|---|---|---|---|---|---|---|---|---|

| SE: Double acting type | 32 40 50 63 80 100 125 |

Blank: Medium carbon steel A: SUS420J2 B: SUS304 C: SUS316 |

Refer to stroke table for details | No this code | Blank: Without magnet S: With magnet |

Blank LB FA FB CA CB CR FTC TC |

Blank: TPU H: Viton N: NBR |

Blank: PT G: G |

| SED: Double rod type | No this code | Blank LB FA FTC TC |

||||||

| SEJ: Adjustable stroke type | 10 20 30 40 50 75 100 |

Blank LB FA FB CA CB CR FTC TC |

[Note1] CR is used with CB; FTC、TC are used with TCM1、TCM2.

ISO15552 Standard cylinder

SE Series

Inner structure and material of major parts

| No. | Item | Material |

|---|---|---|

| 1 | Rod nut | Carbon steel/Stainless steel |

| 2 | Piston rod | Carbon steel with 20 μm chrome plated or Stainless steel |

| 3 | Front cover packing | TPU |

| 4 | Front cover | Aluminum alloy |

| 5 | Bushing | Wear resistant material |

| 6 | Cushion O-ring | TPU |

| 7 | Barrel | Aluminum alloy |

| 8 | O-ring | NBR |

| 9 | Piston | Aluminum alloy |

| 10 | Piston Seal | TPU |

| 11 | Wearing | Wear resistant material |

| 12 | Magnet | Plastic;Rubber(125) |

| 13 | Bolt | Carbon steel |

| 14 | Buffer gasket | TPU |

| 15 | Back cover | Aluminum alloy |

| 16 | Screw | Carbon steel/Stainless steel |

Dimensions

[Dimension drawings/tables placeholder — see page image below]

ISO15552 Standard cylinder

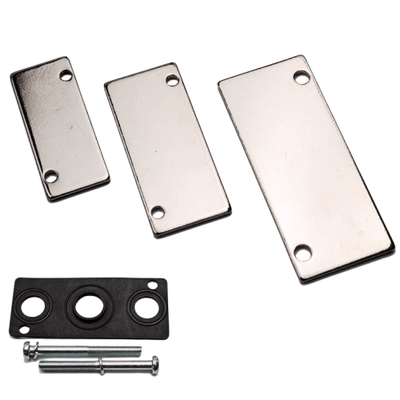

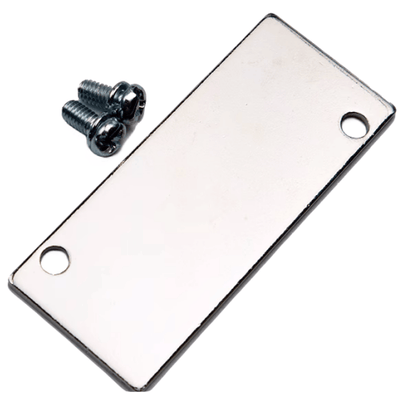

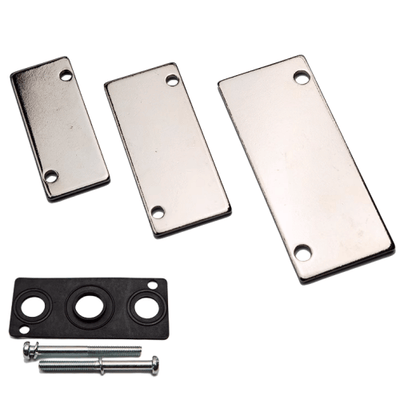

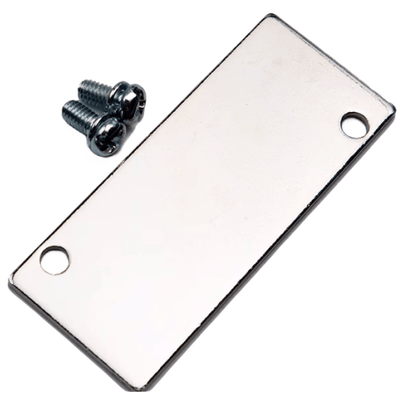

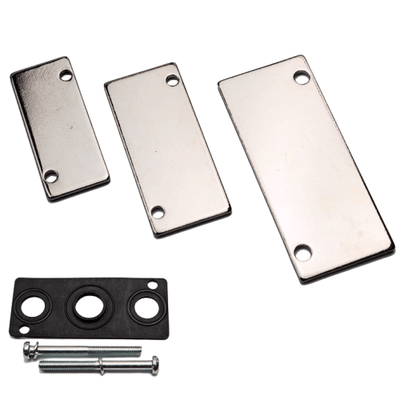

SE Series——Accessories

List for ordering code of accessories

[Accessories ordering list placeholder — see page image below]

Accessory selection

[Accessory selection table placeholder — see page image below]

Material of accessories

[Material of accessories table placeholder — see page image below]

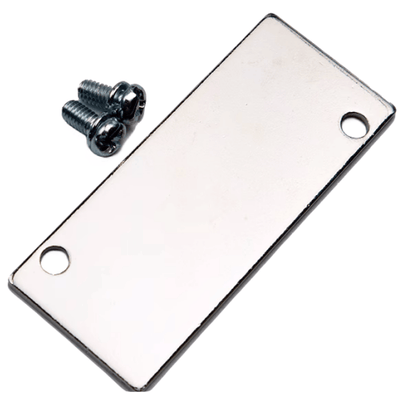

How to mount TC bracket

Please install TC bracket by below steps:

- Hitched half of TC bracket over the barrel, and adjust it to the adapted position.

- Insert the both sides pin of the TC bracket.

- Aimed another half of TC bracket's pin hole at pin and hitched another half of TC bracket over the barrel.

- Putting clamp block in the four row of TC bracket by upper picture.

- Screw down eight locked screws from side face of TC bracket, and lock TC bracket with the max. locking moment of below table; the static clamp force (F) as below table.

| Bore size | Max. locking moment M | Static clamp force F |

|---|---|---|

| 32 | 2~3 N.m | 800 N |

| 40 | 4~6 N.m | 1200 N |

| 50 | 4~6 N.m | 2000 N |

| 63 | 7~12 N.m | 3000 N |

| 80 | 12~20 N.m | 5000 N |

| 100 | 12~20 N.m | 8000 N |

| 125 | 18~30 N.m | 12000 N |

ISO15552 Standard cylinder

SE Series——Accessories

Dimensions

[Dimension drawings/tables placeholder — see page image below]

ISO15552 Standard cylinder

SE Series——Accessories

Dimensions

[Dimension drawings/tables placeholder — see page image below]